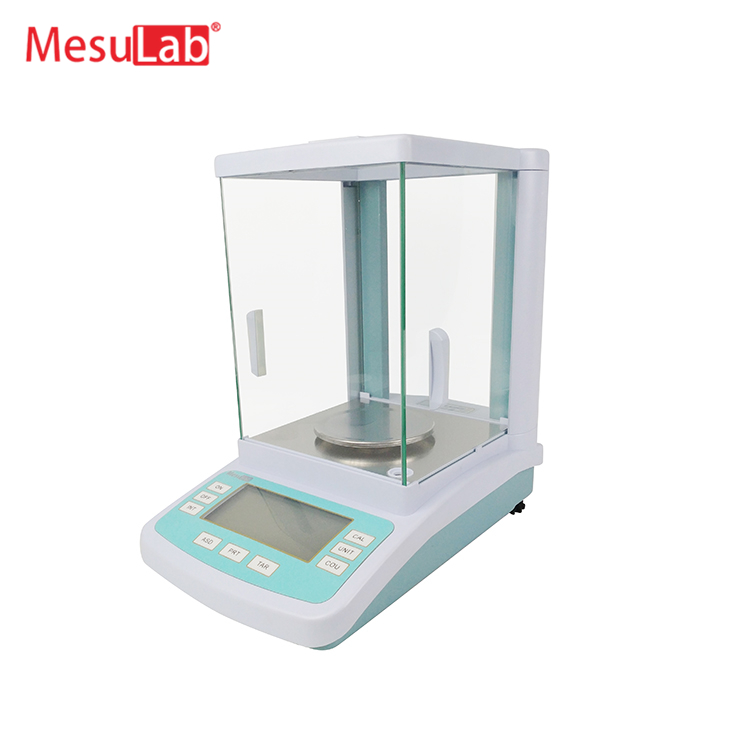

Electronic precision balance is a high-precision measuring tool.

Electronic precision balance plays an important role in modern scientific research, industrial manufacturing and quality control. It is a high-precision measuring instrument, which can accurately measure the mass of objects through electronic sensors and microprocessor technology. This paper will introduce the principle, application field and future development trend.

First of all, electronic precision balance uses piezoelectric sensor or load sensor to detect the force exerted by the object. These sensors can convert the mass applied to the balance into electrical signals, which can be processed and displayed by the built-in electronic devices. Due to the adoption of modern microprocessor technology, it has very high resolution and sensitivity, and can measure quality changes as small as sub-microgram level.

Electronic precision balance is widely used in many fields. In scientific research, it is used for sample preparation and analysis in chemical experiments, biological research and material science. In the pharmaceutical industry, it is used for drug formulation and drug quality control. In industrial manufacturing, it is used for weight detection in the process of machining and assembly of precision parts. In addition, it is also widely used in food, cosmetics and jewelry industries to ensure that the product quality meets the prescribed standards.

With the development of technology, electronic precision balance is also developing. On the one hand, the improvement of sensor technology makes the balance have higher resolution and wider measurement range. On the other hand, with the development of network connection and cloud computing, the balance can realize remote monitoring and data sharing, which improves work efficiency and convenience of information exchange. In the future, it is expected that the balance will continue to evolve and more functions will be integrated, such as temperature and humidity measurement, automatic control and intelligent operation interface.

However, just like any measuring instrument, it needs to be calibrated and maintained frequently to ensure its accuracy and reliability. Users should follow the correct operation method and pay attention to the influence of environmental factors on the measurement results, such as temperature change and vibration interference. In addition, updating the software and firmware of the equipment in time is also an important step to ensure the stability of the balance performance.

In a word, as a high-precision measuring tool, electronic precision balance plays an important role in scientific research, industrial manufacturing and quality control. Through continuous technological innovation and improvement, it will continue to be used in various fields and promote the progress of science and engineering. However, in the process of use, we should also fully understand its principle and precautions to ensure the combination of accuracy and reliability.Electronic precision balance plays an important role in modern scientific research, industrial manufacturing and quality control. It is a high-precision measuring instrument, which can accurately measure the mass of objects through electronic sensors and microprocessor technology. This paper will introduce the principle, application field and future development trend.

First of all, electronic precision balance uses piezoelectric sensor or load sensor to detect the force exerted by the object. These sensors can convert the mass applied to the balance into electrical signals, which can be processed and displayed by the built-in electronic devices. Due to the adoption of modern microprocessor technology, it has very high resolution and sensitivity, and can measure quality changes as small as sub-microgram level.

Electronic precision balance is widely used in many fields. In scientific research, it is used for sample preparation and analysis in chemical experiments, biological research and material science. In the pharmaceutical industry, it is used for drug formulation and drug quality control. In industrial manufacturing, it is used for weight detection in the process of machining and assembly of precision parts. In addition, it is also widely used in food, cosmetics and jewelry industries to ensure that the product quality meets the prescribed standards.

With the development of technology, electronic precision balance is also developing. On the one hand, the improvement of sensor technology makes the balance have higher resolution and wider measurement range. On the other hand, with the development of network connection and cloud computing, the balance can realize remote monitoring and data sharing, which improves work efficiency and convenience of information exchange. In the future, it is expected that the balance will continue to evolve and more functions will be integrated, such as temperature and humidity measurement, automatic control and intelligent operation interface.

However, just like any measuring instrument, it needs to be calibrated and maintained frequently to ensure its accuracy and reliability. Users should follow the correct operation method and pay attention to the influence of environmental factors on the measurement results, such as temperature change and vibration interference. In addition, updating the software and firmware of the equipment in time is also an important step to ensure the stability of the balance performance.

In a word, as a high-precision measuring tool, electronic precision balance plays an important role in scientific research, industrial manufacturing and quality control. Through continuous technological innovation and improvement, it will continue to be used in various fields and promote the progress of science and engineering. However, in the process of use, we should also fully understand its principle and precautions to ensure the combination of accuracy and reliability.